spiral welded steel pipes

Spiral welded steel pipes are a type of pipe manufactured using a special method in which a steel coil is formed and welded using a process known as the Double Submerged Arc Welding (DSAW) method. Here are some key points about spiral welded steel pipes:

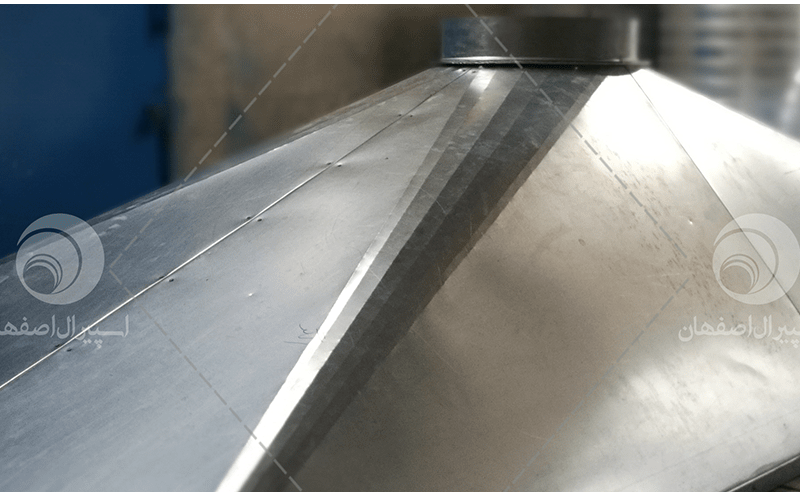

Manufacturing Process:

Spiral welded pipes are manufactured from coils of steel that are unwound and flattened. The flattened strip is formed into a cylinder of the desired diameter using right-angle rollers, and the weld is made under powder coating. This process is also known as Submerged Arc Welding (SAW). At the end of the spiral, a new spiral is welded to the back edge of the pipe, creating a cross seam. The pipe is then cut to length and the ends are beveled if necessary

Advantages:

There are several advantages to using spiral welded pipes. One of the main advantages is that different diameters can be made from the same steel coils, and lengths can be custom made to fit any job requirement. Spiral pipes also have close outside diameter tolerances and are just as easy to weld as regular steel pipes. They are used in large pipeline systems around the world and have favorable properties for stopping a running crack. The strength of spiral-welded pipelines is typically greater than that of straight-seam welded pipelines, making them suitable for various applications in energy, construction, and other industrial sectors

Common Uses:

Spiral welded pipes are commonly used in various industrial and urban sectors for applications such as foundation and structural piling, water and gas transportation, structural applications, and as pile-driving pipes for various structures. They are also used in water systems, particularly those with long lines and large diameters, due to their cost-efficiency compared to other common pipes

In conclusion, spiral welded steel pipes are a versatile and reliable piping material with numerous advantages, making them suitable for a wide range of applications in different industries.

Related products

Reviews

There are no reviews yet.